Tutorial 1 - DXF Trajectory Execution with Laser & Welding Integration

The dxf_script.py is a complete script to perform laser welding using a dxf. The .dxf file must be contained within the workspace bounds (600mm x 800mm). The script also has functionality to scale and center the dxf to parse (x,y) coordinates for robot poses. The script is written using only ROS services to control peripherals. The code is explained below:

This tutorial walks through loading a DXF file, parsing it into robot poses, and executing a Cartesian welding trajectory using ROS1. Laser and weld control are also integrated via services.

1. Prerequisites

Install required Python packages:

pip install ezdxf numpy

Ensure the following ROS services are available and active:

/real/fc_set_pose/real/fc_execute_cartesian_trajectory_async/weld_start,/weld_end/laser_emit_start,/laser_emit_stop/laser_ready_arm,/laser_disarm/set_io_value

2. Load and Parse the DXF File

import ezdxf

from geometry_msgs.msg import PoseStamped

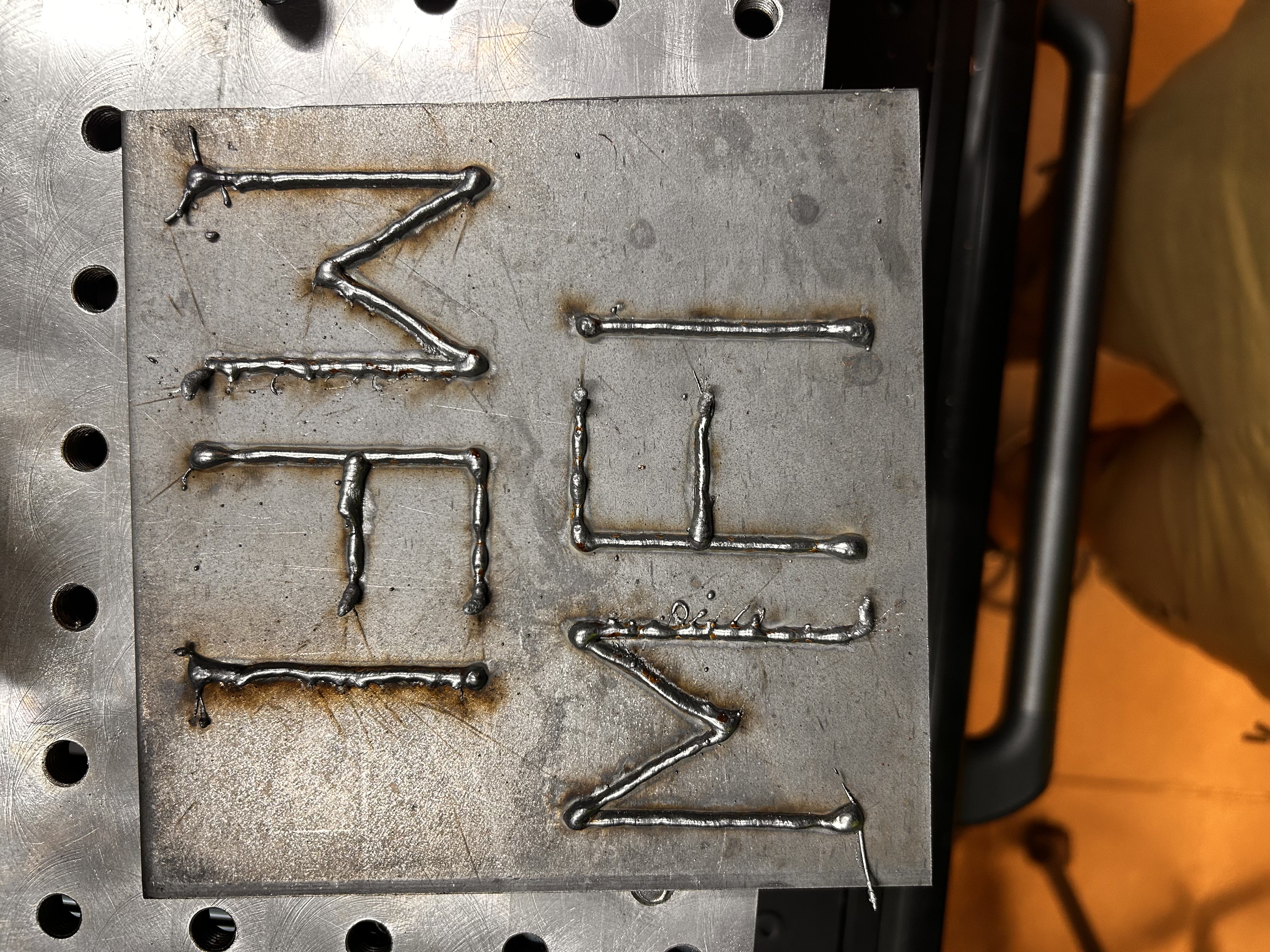

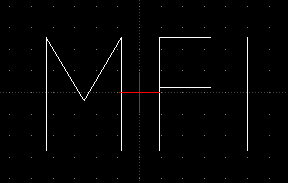

DXF_FILE_PATH = "/root/ros1_ws/src/le_classmate_ros/data/MFI8.dxf"

FIXED_Z = 0.405

FIXED_QUAT = (0.707, 0, 0.707, 0)

def parse_dxf_to_poses(dxf_file) -> list:

doc = ezdxf.readfile(dxf_file)

msp = doc.modelspace()

poses = []

for line in msp.query("LINE"):

for pt in [line.dxf.start, line.dxf.end]:

pose = PoseStamped()

pose.pose.position.x = pt[0]

pose.pose.position.y = pt[1]

pose.pose.position.z = FIXED_Z

pose.pose.orientation.x, pose.pose.orientation.y, pose.pose.orientation.z, pose.pose.orientation.w = FIXED_QUAT

poses.append(pose)

return poses

This function reads a DXF file and extracts LINE entities, converting them into 3D ROS poses with a fixed height and orientation.

3. Center and Scale the Path

import numpy as np

def transform_to_centre(center_x, center_y, poses, scale):

delta_x = center_x - 0.53

delta_y = center_y - 0.01

transform_matrix = np.array([[1, 0, 0, -delta_x], [0, 1, 0, -delta_y], [0, 0, 1, 0], [0, 0, 0, 1]])

for pose in poses:

p = [pose.pose.position.x, pose.pose.position.y, pose.pose.position.z, 1]

p_new = np.dot(transform_matrix, p)

pose.pose.position.x = p_new[0] * scale

pose.pose.position.y = p_new[1] * scale

return poses

This function recenters the poses around a fixed workspace origin and scales them to fit the robot’s reach.

4. Monitor Tool Pose and Trigger IO

import math

def calculate_pose_error(pose1, pose2):

dx = pose1.pose.position.x - pose2.pose.position.x

dy = pose1.pose.position.y - pose2.pose.position.y

dz = pose1.pose.position.z - pose2.pose.position.z

return math.sqrt(dx**2 + dy**2 + dz**2), 0.0 # Orientation skipped for simplicity

def monitor_pose_callback(msg, targets):

for i, (idx, target_pose, action) in enumerate(targets):

if idx in found_targets: continue

prev_ok = (i == 0) or (targets[i-1][0] in found_targets)

error, _ = calculate_pose_error(msg, target_pose)

if error < 0.001 and prev_ok:

found_targets.add(idx)

LaserOn(True) if action == "on" else LaserOff(True)

weldOn(True) if action == "on" else weldOff(True)

The monitor_pose_callback is a subscriber callback that triggers welding and laser IO actions when the robot’s pose reaches specified targets within tolerance.

5. Initialize ROS Node and Services

import rospy

from fc_msgs.srv import ExecuteCartesianTrajectory, SetPose, SetIO

from le_classmate_ros.srv import LaserEmit, Weld, LaserArm

from geometry_msgs.msg import PoseStamped

import comet_rpc as rpc

import time

rospy.init_node('dxf_trajectory')

# Wait for required services

rospy.wait_for_service('/real/fc_set_pose')

rospy.wait_for_service('/real/fc_execute_cartesian_trajectory_async')

rospy.wait_for_service('/weld_start')

rospy.wait_for_service('/weld_end')

rospy.wait_for_service('/laser_emit_start')

rospy.wait_for_service('/laser_emit_stop')

rospy.wait_for_service('/set_io_value')

rospy.wait_for_service('/laser_ready_arm')

rospy.wait_for_service('/laser_disarm')

rospy.wait_for_service('/set_override')

# Create service proxies

set_pose = rospy.ServiceProxy('/real/fc_set_pose', SetPose)

execTraj = rospy.ServiceProxy('/real/fc_execute_cartesian_trajectory_async', ExecuteCartesianTrajectory)

weldOn = rospy.ServiceProxy('/weld_start', Weld)

weldOff = rospy.ServiceProxy('/weld_end', Weld)

LaserOn = rospy.ServiceProxy('/laser_emit_start', LaserEmit)

LaserOff = rospy.ServiceProxy('/laser_emit_stop', LaserEmit)

Set_IO = rospy.ServiceProxy('/set_io_value', SetIO)

Laser_Arm = rospy.ServiceProxy('/laser_ready_arm', LaserArm)

Laser_Disarm = rospy.ServiceProxy('/laser_disarm', LaserArm)

set_override = rospy.ServiceProxy('/set_override', Trigger)

This block initializes your ROS node and service clients needed to control the welding process.

6. Setup Monitoring, Execute Trajectory

poses = parse_dxf_to_poses(DXF_FILE_PATH)

found_targets = set()

# Save poses to file for debugging

with open('/root/ros1_ws/src/le_classmate_ros/data/poses.txt', 'w') as f:

for i, p in enumerate(poses):

f.write(f"{i} - {p.pose.position.x}, {p.pose.position.y}, {p.pose.position.z}\n")

# Monitor only certain indices

to_monitor_off_indices = [4,7,9]

to_monitor_on_indices = [5,8,10]

combined_targets = [(i, poses[i], "off") for i in to_monitor_off_indices] + [(i, poses[i], "on") for i in to_monitor_on_indices]

combined_targets.sort()

rospy.Subscriber('/real/tool0_pose', PoseStamped, monitor_pose_callback, callback_args=(combined_targets,))

This section selects key trajectory points to monitor and binds them to the callback for IO control.

7. Begin Motion Execution

# Move to starting pose

set_pose(poses[0].pose, '/base_link', 0.3, 0.1, 'PTP')

# Setup welding systems

set_override(100) # Ensure override is set to 100

Set_IO('Digital_OUT', 47, 1)

Laser_Arm(True)

time.sleep(2)

LaserOn(True)

weldOn(True)

# Execute trajectory

execTraj([p.pose for p in poses], 0.01, 0.0, 0.01, 0.01, 0.0)

# Shut down

weldOff(True)

set_pose(poses[-1].pose, '/base_link', 0.3, 0.1, 'PTP')

LaserOff(True)

Laser_Disarm(True)

Finally, the robot moves through the full trajectory, with laser/weld triggered as it hits waypoints. After execution, the system is shut down cleanly.

Summary

Parse DXF into

PoseStampedwaypointsScale/center into workspace

Monitor robot motion and trigger actions using

SubscriberExecute path with real-time IO via

ServiceProxy

This pattern can be reused for painting, welding, inspection, and more.

Tutorial 2 - ROS Welding Routine Explained

This Python script performs a simple two-pass laser welding operation using predefined poses and ROS service calls. Below is a breakdown of the key parts of the code.

1. Imports and Constants

import rospy

import ezdxf

import tf

import math

import numpy as np

from geometry_msgs.msg import Pose, PoseStamped

from fc_msgs.srv import ExecuteCartesianTrajectory, SetPose

from ezdxf.math import BoundingBox2d, Vec2

import comet_rpc as rpc

import time

from le_classmate_ros.Welding import Welder

from le_classmate_ros.srv import LaserArm, LaserEmit, Weld, SetIO

from std_srvs.srv import Trigger

These import necessary libraries for ROS control, DXF processing, math, and I/O. The services and message types are specific to a laser welding robot setup.

2. Fixed Parameters and Pose Definitions

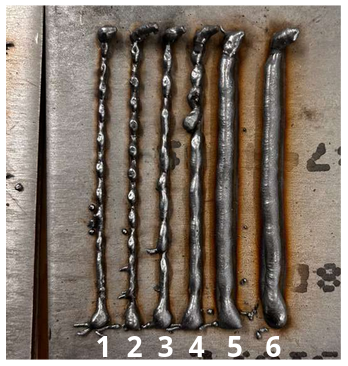

FIXED_Z_1 = 0.403

FIXED_Z_2 = 0.405

FIXED_QUAT = (-0.707, 0 , -0.707, 0)

FIXED_Y = 0.02

We define fixed heights and orientations for the welding tool. Then we create 4 poses: two for the first weld path, and two for the second (slightly offset in Z).

PointA_1 = PoseStamped()

PointA_1.pose.position.x, PointA_1.pose.position.y, PointA_1.pose.position.z = 0.51, FIXED_Y, FIXED_Z_1

PointA_1.pose.orientation.x, PointA_1.pose.orientation.y, PointA_1.pose.orientation.z, PointA_1.pose.orientation.w = FIXED_QUAT

This is repeated similarly for PointB_1, PointA_2, PointB_2.

3. Main Execution Block

if __name__ == '__main__':

rospy.init_node('dxf_trajectory')

We initialize the ROS node and wait for all required services to be available.

4. Service Clients Setup

set_pose = rospy.ServiceProxy('/real/fc_set_pose', SetPose)

execTraj = rospy.ServiceProxy('/real/fc_execute_cartesian_trajectory_async', ExecuteCartesianTrajectory)

...

These are the clients used to command robot motion, welding, and laser behavior.

5. Enabling welding

set_override(100) # Set override to 100

Set_IO('Digital_OUT', 47, 1) # Enable external control

We set the necessary flags to enable external control and welding.

6. Welding Routine

First Pass:

set_pose(PointA_1.pose, '/base_link', 0.01, 0.1, 'PTP')

Laser_Arm(True)

time.sleep(2)

LaserOn(True)

weldOn(True)

set_pose(PointB_1.pose, '/base_link', 0.0075, 0.1, 'PTP')

weldOff(True)

LaserOff(True)

We move to start position, arm the laser, begin welding, move to the end point, and stop.

Second Pass:

set_pose(PointA_2.pose, '/base_link', 0.01, 0.1, 'PTP')

LaserOn(True)

weldOn(True)

set_pose(PointB_2.pose, '/base_link', 0.001, 0.1, 'PTP')

weldOff(True)

set_pose(PointB_2.pose, '/base_link', 0.3, 0.1, 'PTP') # Move away

LaserOff(True)

Laser_Disarm(True)

Same as the first pass, but slightly higher in Z (a “second layer” weld).

7. Summary

This code executes a controlled laser weld routine along two horizontal lines using ROS services. Each phase—arming, emitting, welding, and disarming—is explicitly timed and ordered.

To extend this:

Add more poses to trace complex geometries.

Convert DXF lines to pose sequences.

Add feedback/error handling for real deployments.

Tutorial 3 - Using the Welder Class Without ROS

The Welding.Welder class can be used directly in standalone Python scripts to control welding I/O over RPC (comet_rpc):

from fanuc_ros1.le_classmate_ros.src.Welding import Welder

import comet_rpc as rpc

import time

'''

def vmip_writeva(

server: str, prog_name: str, var_name: str, value: t.Union[str, int, float]

) -> VmIpWriteVaResponse:

"""Write 'value' to the variable 'var_name' in program 'prog_name'.

Set `prog_name` to `"*SYSTEM*"` to write to system variables.

`value` will always be submitted as a string, even for (system) variables

which are of a different type. `COMET` apparently tries to parse the

string representation and converts it to the required type when possible.

The string representations are expected to be identical to those found in

`.VA` files.

OVERRIDE is a system variable which can be set to a value between 0 and 100. It needs to be set to 100 to allow welding and movement.

the prog_name is "*SYSTEM*" as override is a system variable

THIS MUST BE DONE BEFORE EVERY PROGRAM RUN TO ENSURE THAT OVERRIDE IS SET TO 100. NOT DOING SO WILL RESULT IN AN ERROR WHEN TRYING TO START WELDING.

The override value is set to 100 in the constructor of the Welder class, however, it still may need to be set again here.

Best practice is to always set it in every program.

'''

if __name__ == '__main__':

# Setting up the server

server = '192.168.2.151'

welder = Welder(server=server)

# Setting overwrite to 100 - refer to the docstring of vmip_writeva above for more information

rpc.vmip_writeva(server, "*SYSTEM*", "$MCR.$GENOVERRIDE", value=100)

# Enabling external control - i/o value that control the external control must be set to 1

rpc.iovalset(server, rpc.IoType.DigitalOut, index=47, value=1)

# Arming the Laser

welder.laser_ready_arm()

# Starting Laser Emission

welder.laser_start_emit()

# Starting welding (robot must be in motion when this state is active)

welder.weld_start()

# Move the robot here using your preferred method

# Stopping welding

welder.weld_end()

# Stopping Laser Emission

welder.laser_stop_emit()

# Disarming the Laser

welder.laser_disarm()

The class handles all relevant I/O mappings and safety interlocks. An example is shown in scripts/welder_class_example.py